Bulk Material Aeration & Fluidization | Silo accessories

Air loosening spots

Air loosening spots or air dispersal spots are suitable for large-area and punctual injection of compressed air into the silo. They are used for dusty and highly cohesive bulk materials such as cement, flour, lime or salt. Made of food-grade stainless steel, the spots assist in discharging the bulk material as a fluidizing aid and in aerating the material during long-term storage. In principle, air fluffing spots are suitable for most dusty bulk materials.

- Description

- Dimensions

- Data sheets

Our air loosening spots can easily be retrofitted to silos, hoppers and bunkers. For this purpose, the container must be accessible from the inside. In principle, they can be used for all dusty bulk materials, at individual points for flow improvement (fluidization) or over a larger area in the field system. Suitable for use in contact with foodstuffs, as they are made entirely of stainless steel. Economical operation can be achieved, for example, with a side-channel compressor. We offer our aeration spots in two different versions: with one-sided (type AM-1) or double-sided (type AM-2) porous surface.

The part of the aeration spot that protrudes into the vessel consists of a highly porous sintered material through which compressed air can escape over a wide area. The two-dimensional introduction of compressed air into a stored bulk material can be used for fluidization (important during discharge) or for aeration/ventilation during storage.

The highly porous aeration surface made of 1.4404 stainless steel is food safe and can be used at operating temperatures up to 500°C (reducing) or up to 400°C (oxidizing). The aeration spots are virtually maintenance-free in operation.

They are used for fine powdered bulk material, the operating pressure is up to 0.4 bar. Alternatively, we recommend our air loosening nozzles or vibratory aerators VBS and VBSI, and our aeration fields for more extensive air input.

Under certain conditions or circumstances, inerting with our air loosening spots, as an alternative to ANIF aeration nozzles, is also possible.

Installation of aeration spot

A hole with a diameter of 28 mm is made in the hopper wall, the fluidizing spot is pushed through from the inside and screwed tight with gasket and nut (included in delivery). Now only the air supply has to be connected. Done!

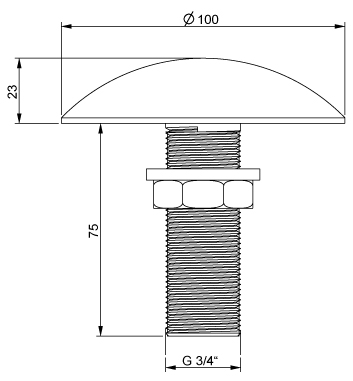

Luftauflockerungsspot AM-1

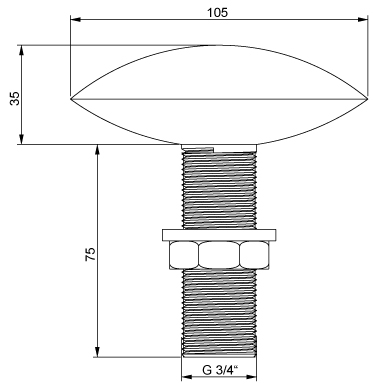

Luftauflockerungsspot AM-2