Bulk Material Aeration & Fluidization | Silo accessories

Vibration Aerator VBS/VBSI

Vibration Aerators combine the injection of compressed air (working pressure up to 6 bar) and the generation of light vibrations on the silo wall. They represent a gentle alternative to the application of a compressed air hammer or compressed air interval tapper, as they have a considerably lower structural load. Existing silos can be easily converted to Vibration Aerators. For particularly high demands, the VBSI version is equipped with a stainless steel shaft. Our Vibration Aerators have FDA approval and are therefore approved for use with foodstuffs.

- Description

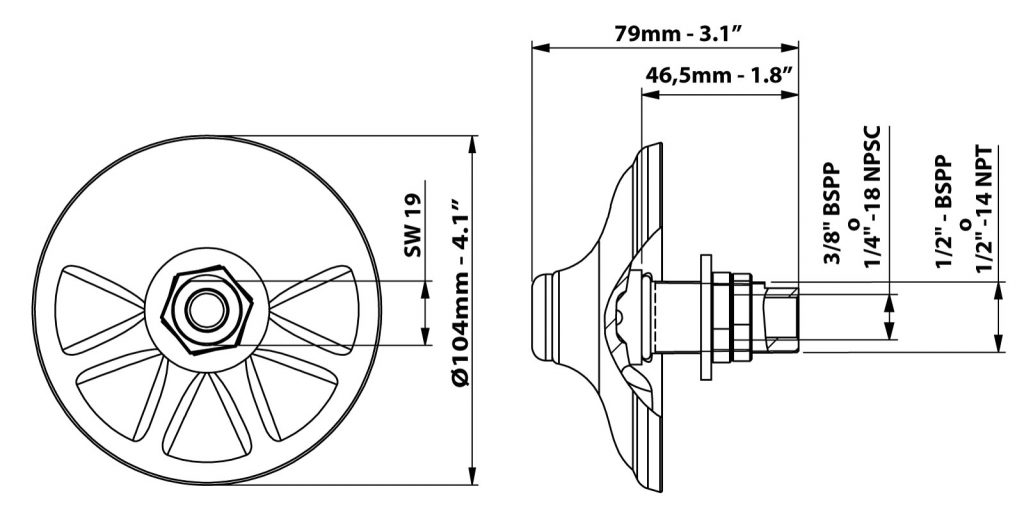

- Dimensions

Vibration Aerators are used for material flow improvement and aeration of powders and granules. They combine material aeration with additional light vibrations of the silo wall and are a gentle alternative to compressed air knockers and pneumatic hammers, as they have a considerably lower structural load.

Installation of the Vibration Aerators is relatively simple. A hole is drilled in the wall of the silo or hopper, the Vibration Aerator is pushed through, tightened with a nut, and the compressed air supply is connected. Done!

Compressed air is discharged directly into the material via the silicone lip that rests against the inner wall of the silo. A variation of the working pressure changes the vibration strength of the silicone lip. Due to clocked operation and the maximum required working time of 5 seconds, the air consumption is extremely low.

Due to the design, damage to the silo wall is excluded even with abrasive products. The Vibration Aerators have a robust design and are self-cleaning. Additional non-return valves are not required, as the working pressure (2 to 6 bar) means that no product can get under the supple silicone lip. This is made of a silicone rubber that complies with BfR and FDA regulations for contact with food. Thus, its use in the food sector is permissible.

Products successfully tested with VBS: Cement, sand, lime, calcium carbonate, sugar, flour, additives, diatomaceous earth, talc, filler, dolomite, soda ash, feldspar, pellets, limestone, stoneware atomized, etc.

Versions

For special requirements a version with stainless steel shaft (type VBSI), a metal detectable version (type VBSI-MD), a miniature version for small hoppers and radii (type VBSM/VBSMI) as well as a version for external mounting (type VBE) are available.

Field of application

The Vibration Aerators are suitable for the following applications:

- Emptying aid for containers

- Maintaining material flow and releasing product jams

Pressure/temperature

The Vibration Aerators are operated with 2 to 6 bar compressed air. The frequency of vibration can be increased/decreased by throttling the air supply.

The operating temperature is -40°C to +170°C.

Vibrationsbelüfter VBS - Abmessungen

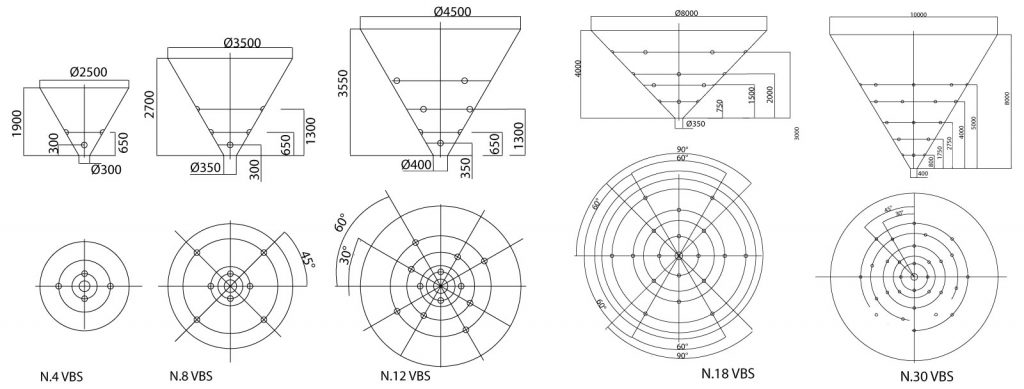

Vibrationsbelüfter VBS - Anordnung