Bulk Material Aeration & Fluidization

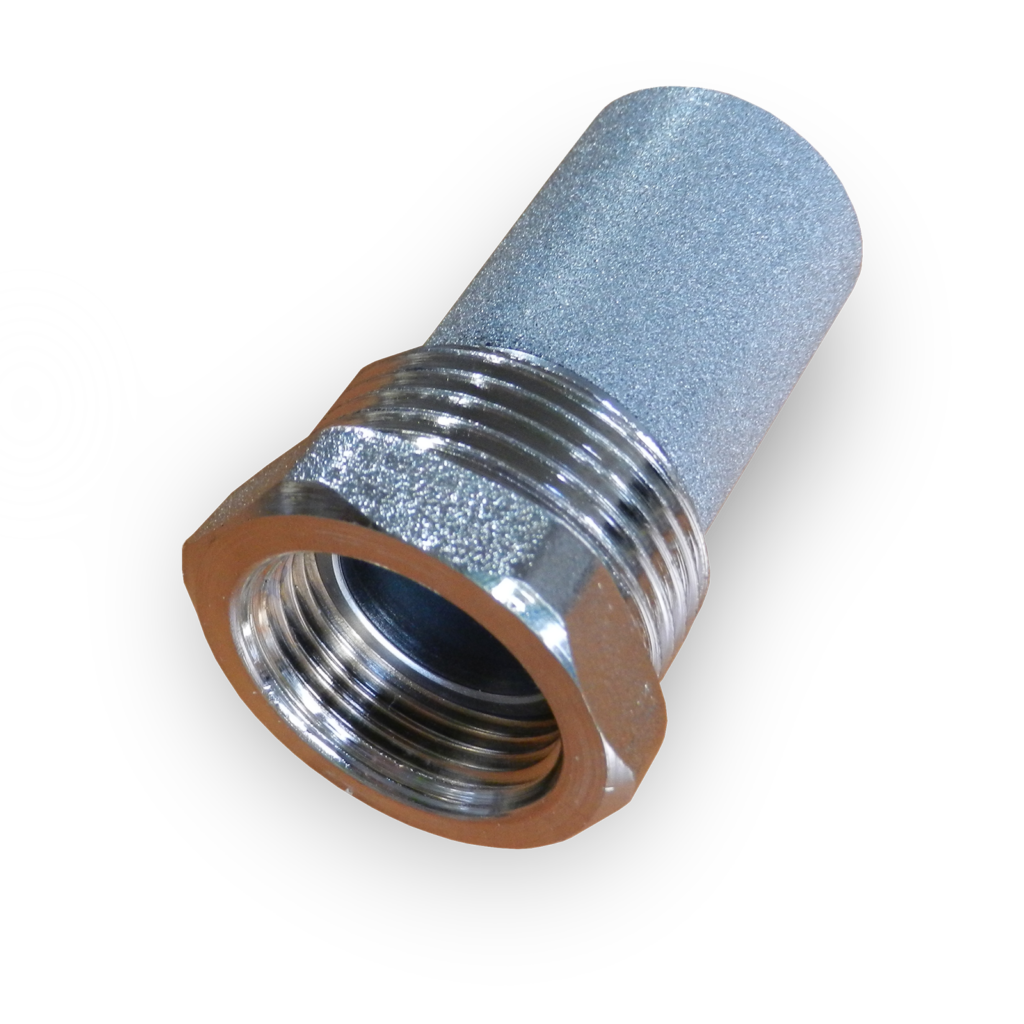

Air loosening nozzles ANI / ANIF

ANI / ANIF air agitation nozzles completely made of stainless steel for the selective injection of compressed air into the silo for fluidization. They are used for dusty and highly cohesive bulk materials such as cement, flour, lime or salt. They are particularly suitable for food storage and corrosive bulk materials or environments. The air agitation nozzles support the discharge of the bulk material as a fluidizing aid and the aeration of the material during long-term storage. In principle, most dusty bulk materials can be treated successfully.

- Description

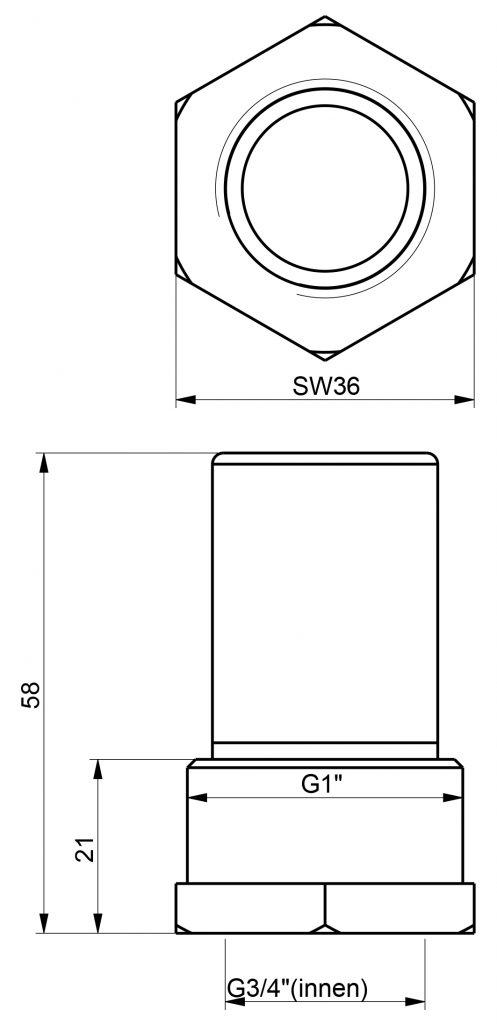

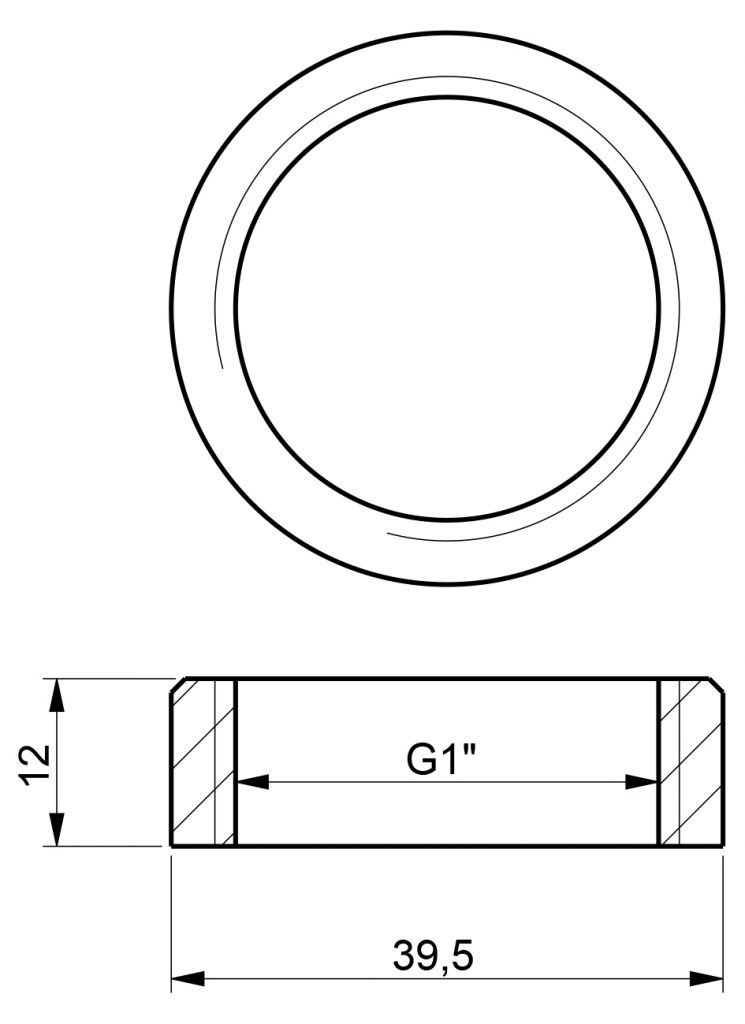

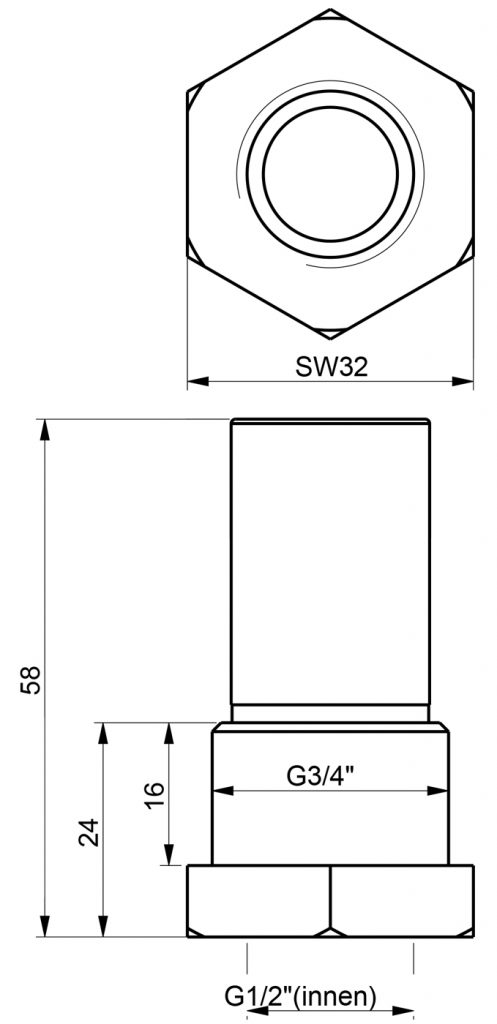

- Dimensions

- Data sheets

Stainless steel variant

Our air loosening nozzles ANI / ANIF provide for the injection of compressed air at the silo wall and are used for dusty and strongly cohesive bulk materials such as cement, flour, lime or salt. In this case, they support the discharge of the bulk material from the cone by ensuring that it is loosened up with air.

They have a head made of sintered stainless steel (1.4404), which is permeable to compressed air. This head protrudes into the container and ensures very fine distribution of air in the bulk material.

The nozzle insert with the sintered metal head must be screwed into a stainless steel sleeve welded to the silo wall (available as an option) and connected to the air supply. Done!

It is used for fine powdered bulk material, the operating pressure is approx. 2 bar. Practical experience has shown that, in principle, all dusty bulk materials can be successfully treated with air disintegration nozzles in intermittent operation (Pulse-Jet and Felder system).

- Support of the material flow

- Fluidizing for discharge

- Aeration of bulk material during storage

Can be used, for example, in the food and pharmaceutical industries, on hoppers and containers. Stainless steel aeration nozzles are largely maintenance-free.

Inerting is also possible: the ANIF variant is excellently suited for injecting inert gas into fire- and explosion-hazardous deposits.

Special designs

For special requirements such as special environments, deviating dimensions or special installation conditions, our aeration cartridges are also available in a variety of special designs. The aeration plugs can be made of 1.4404 stainless steel with different porosity grades.

- Operating temperatures up to 450°C (reducing) or up to 400°C (oxidizing)

- Mounting from outside with welded sleeves (optionally available, 1.4404 or 1.4571)

- Mounting from outside with welded-on threaded socket

- Aeration plugs are virtually maintenance-free in operation.

For applications where there is contact with foodstuffs and the compressed air input is not sufficient, we recommend alternatively our air loosening spots made of stainless steel or vibration aerators VBS and VBSI.

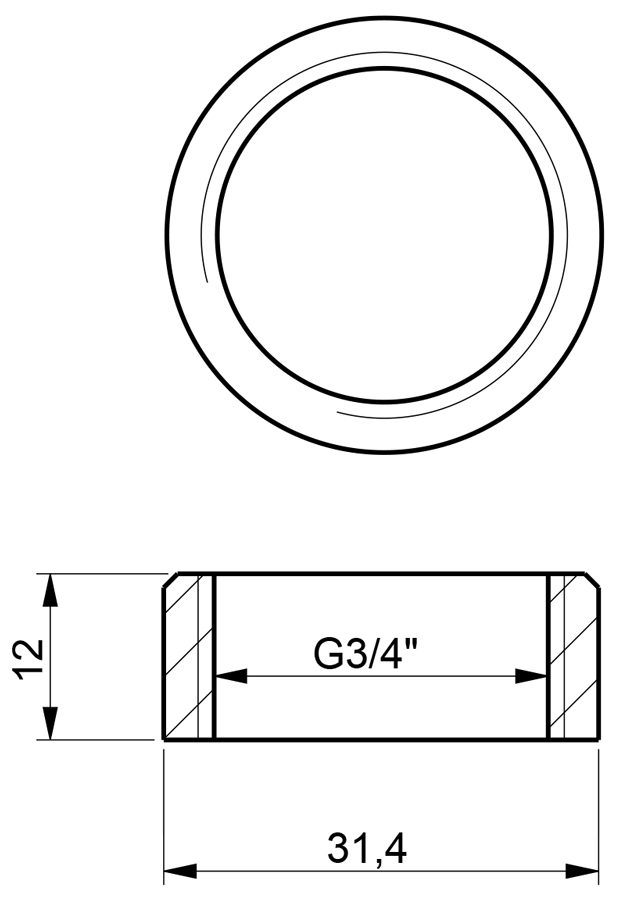

ANI-1-Kerze

ANI-1-Muffe

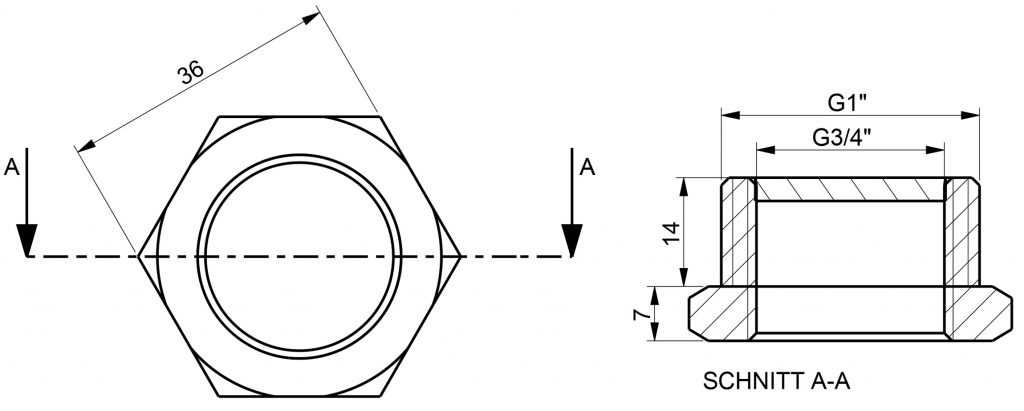

ANI-34-Kerze

ANI-34-Muffe

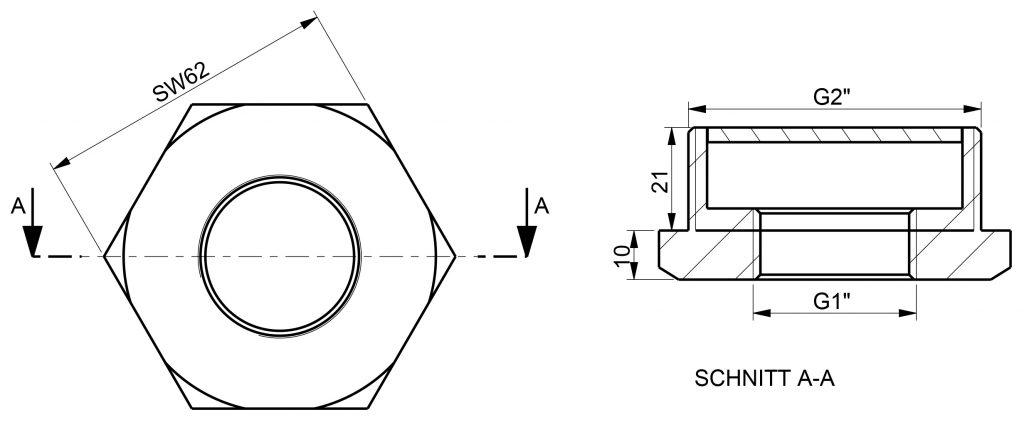

ANIF-1-Kerze

ANIF-2-Kerze