Bulk Material Aeration & Fluidization | Silo accessories

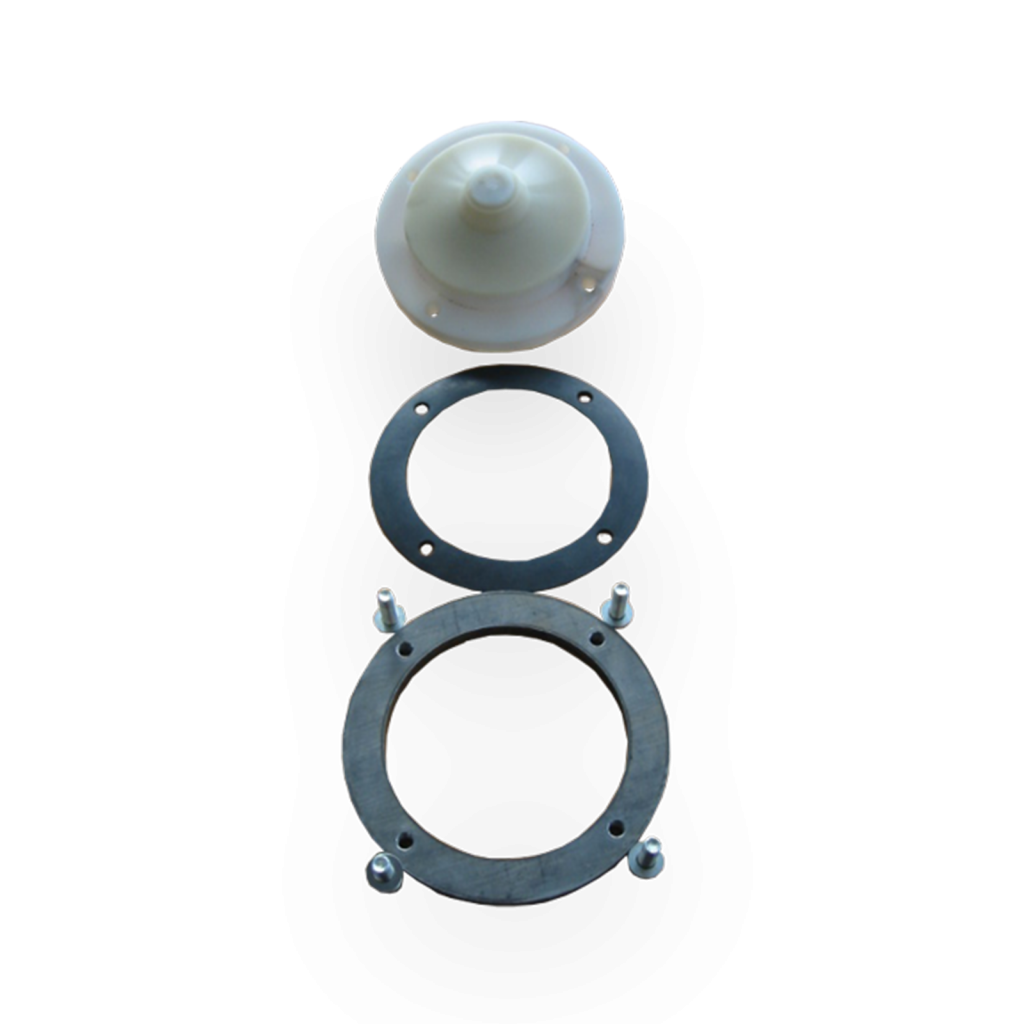

Vibration aerator VBE

The VBE vibratory aerators are a special design for external mounting of the proven VBS vibratory aerators. The VBE vibration ventilators are designed for retrofitting to the outer wall of silos and hoppers when access from the inside is not possible or difficult.

- Description

Vibratory aerators are used for material flow improvement and aeration of powders and granules. They combine material aeration with additional slight vibrations of the silo wall and are a gentle alternative to compressed air knockers and pneumatic hammers, as they have a considerably lower structural load.

If installation is only possible via external access, our VBE external vibration ventilators come into play.

Compressed air is discharged directly into the material via the silicone lip that rests against the inner wall of the silo. A variation of the working pressure changes the vibration strength of the silicone lip. Due to clocked operation and the maximum required working time of 5 seconds, the air consumption is extremely low.

Due to the design, damage to the silo wall is excluded even with abrasive products. The vibratory aerators have a robust design and are self-cleaning. Additional non-return valves are not required, as the working pressure (2 to 6 bar) means that no product can get under the supple silicone lip. This consists of a silicone rubber with FDA approval, thus the use in the food sector is permissible.

From the series of vibratory aerators, the standard versions for internal mounting (type VBS & VBSI) or the miniature version for internal mounting (type VBSM & VBSMI) are still available.

Vibratory aerators have been successfully tested on the following products: Cement, sand, lime, calcium carbonate, sugar, flour, additives, diatomaceous earth, talc, filler, dolomite, soda ash, feldspar, limestone, stoneware atomized, etc.

Pressure/temperature

The vibratory aerators are operated with 2 to 6 bar compressed air. The frequency of the vibration can be increased/decreased by throttling the air supply.

The operating temperature is -40°C to +170°C.