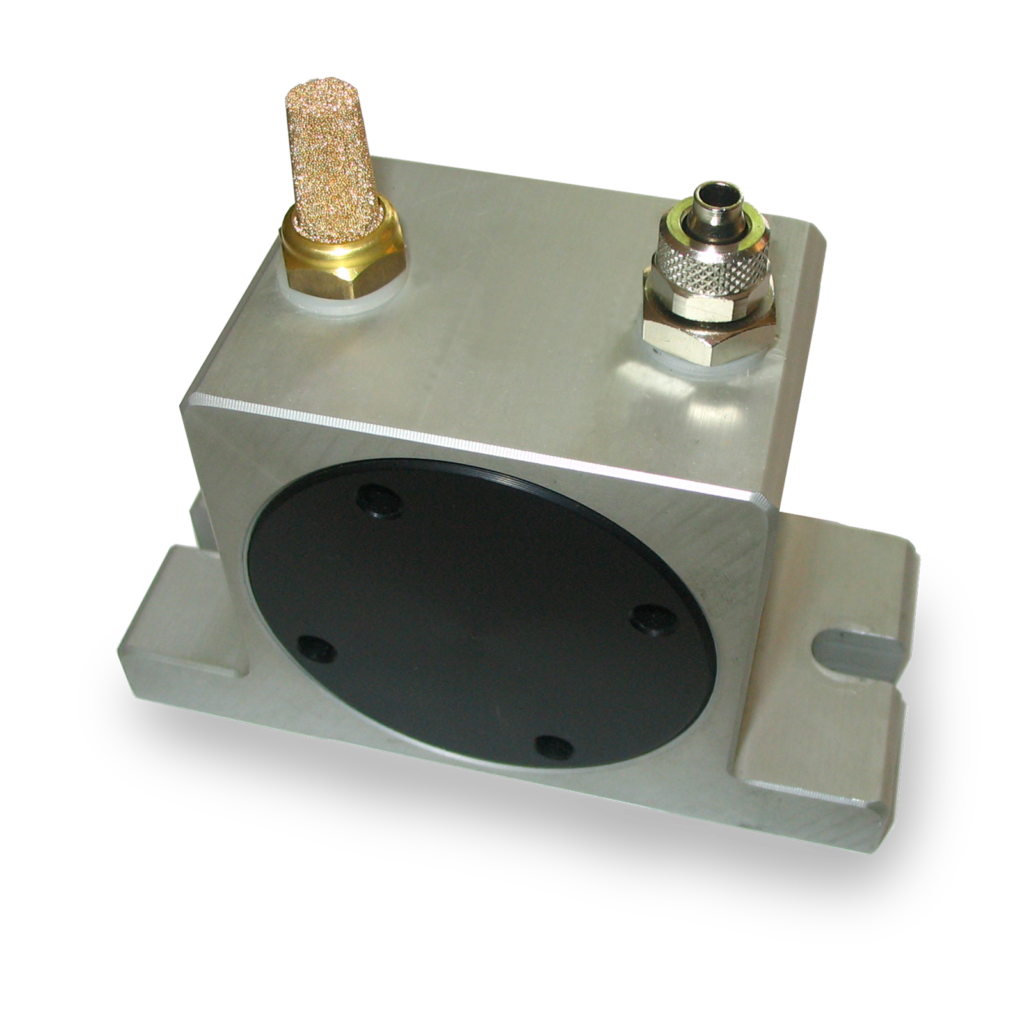

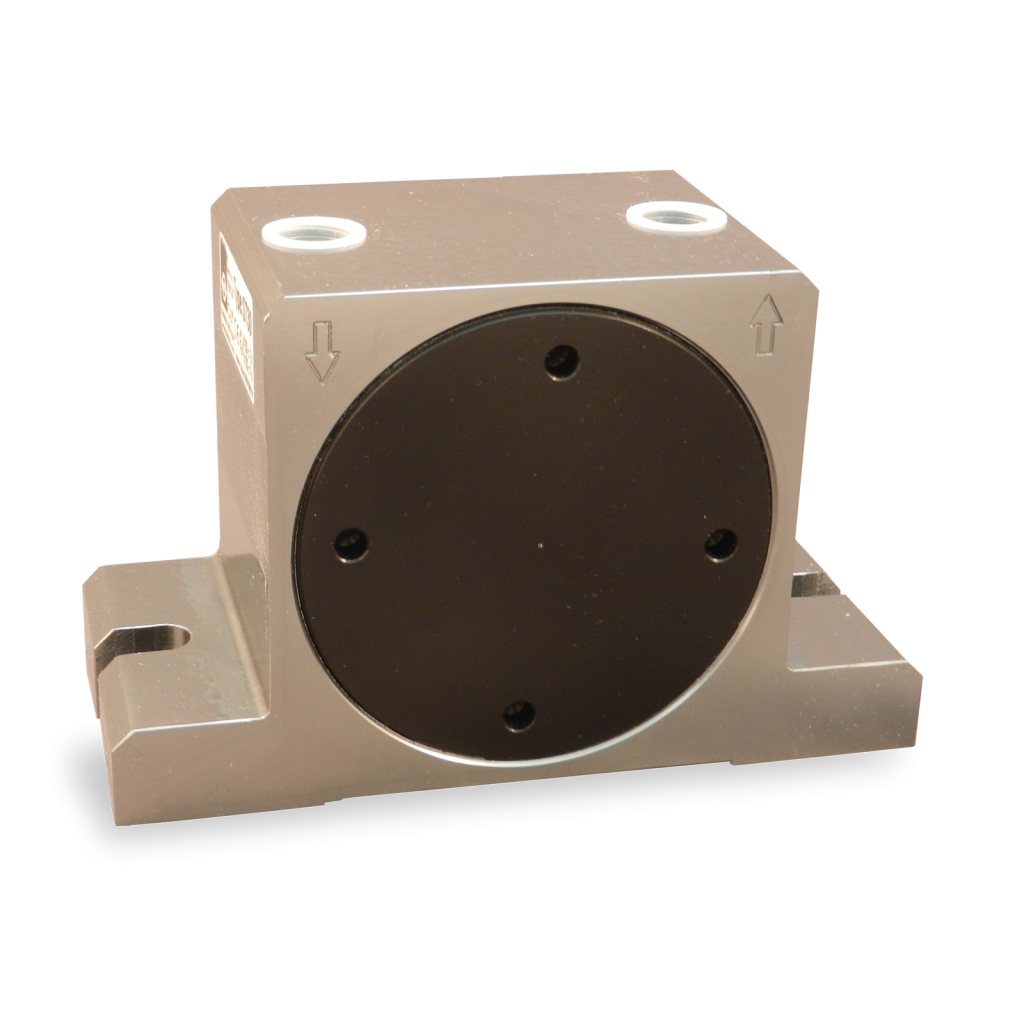

Turbine vibrators, maintenance-free

Turbine vibrators have a rotor which is designed as a compressed air turbine. This is equipped with eccentrically arranged weights for unbalance generation.

The bearings of the turbine shaft consist of high-quality bearings designed for continuous operation. The turbine vibrators allow the use of unlubricated compressed air and are completely maintenance-free. They are also characterized by high speeds and low air consumption.

- Description

- Performance data

- Dimensions

- Data sheets

Turbine vibrators belong to the class of pneumatically driven vibrators. They serve a wide variety of tasks in bulk material and unit load conveying technology, industrial automation and silo technology. Fields of application:

- Material flow support

- Screening

- Compacting of powders and granulates

- Sorting

- Dissolving

- Conveying

- Cleaning with the aid of vibration

A turbine vibrator can be used, for example, in the food and pharmaceutical industries, on small hoppers, containers, classifiers or screening plants. All that is required is to lay a compressed air line and attach the turbine vibrator. A compact turbine vibrator is ideal for maintaining the material flow in confined areas of the production process and is completely maintenance-free.

The housing of the turbine vibrator is made of an aluminum alloy and protected against corrosion by an anodized coating. Inside the housing, a compressed air turbine equipped with unbalanced weights is guided in two ball bearings. The housing is completely closed, thus no dirt can penetrate and damage the turbine vibrator.

Compressed air turbine vibrators develop high centrifugal forces and run reliably in any installation position due to the close pitch of the turbine blades. The turbine shaft bearing consists of generously dimensioned and sealed ball bearings that are lubricated for life. This allows a turbine vibrator to be used completely maintenance-free, making it the first choice for a wide range of applications.

Our turbine vibrators are available in twelve different sizes. Alternatively, our ball vibrators or our roller vibrators can also be used.

Field of application

Turbine vibrators are suitable for the following tasks, among others:

- Vibration drive for small vibrating tables, chutes or screens

- Preventing build-up on the walls of bunkers, hoppers, bins and silos

- Discharge aid for bulk material bins

- Maintaining the flow of material

- Loosening of product jams for bulk material and piece goods

- Vibration conveyor aid for filling, transfer and production plants

Vibration

Vibration is generated by means of a rotor, which is designed as a compressed air turbine and is supplied with compressed air through a nozzle. The rotor has one or more eccentrically arranged weights, which lead to an imbalance of the rotating shaft. As a result, the turbine vibrators generate a circular oscillation.

The turbine shaft is mounted in two generously dimensioned ball bearings suitable for continuous operation at high speeds. These allow high efficiency and, because they are lubricated for life, enable the use of unlubricated compressed air.

Pressure/Temperature

The vibrators are operated with up to 6 bar of compressed air. By throttling the air supply (between 2 and 6 bar), the frequency and strength of the vibration can be increased/decreased.

The standard operating temperature is -20°C to +120°.

A 2/2 way valve and filtered compressed air are required for operation. The turbine vibrators can be operated without lubricated compressed air as the rotor ball bearings are lubricated for life.

Protection/Safety

The enclosed silencer ensures quiet operation, also there is an explosion protection according to the following ATEX classification:

ATEX Zone 21 II 2D c T95°C/125°C Zone 1 II 2G c T5/T4.

| Drehzahl u/min | Kraft kn | Luftverbrauch l/min | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Typ | 2 bar | 4 bar | 6 bar | 2 bar | 4 bar | 6 bar | 2 bar | 4 bar | 6 bar |

| OT8 | 34.000 | 38.000 | 42.000 | 1,08 | 2,01 | 2,86 | 45 | 81 | 110 |

| OT10 | 26.000 | 33.000 | 38.000 | 1,03 | 1,68 | 2,47 | 45 | 81 | 110 |

| OT10S | 17.200 | 23.400 | 26.000 | 0,71 | 1,44 | 1,83 | 45 | 81 | 110 |

| OT13 | 24.500 | 28.500 | 31.000 | 1,98 | 2,58 | 2,94 | 122 | 204 | 285 |

| OT16 | 18.000 | 20.000 | 21.000 | 1,90 | 2,34 | 2,59 | 122 | 204 | 285 |

| OT16S | 11.500 | 15.000 | 17.500 | 1,27 | 1,92 | 2,30 | 122 | 204 | 285 |

| OT20 | 14.500 | 19.000 | 23.000 | 2,46 | 3,96 | 5,16 | 184 | 318 | 452 |

| OT25 | 13.200 | 15.500 | 17.000 | 2,39 | 3,30 | 4,98 | 184 | 318 | 452 |

| OT25S | 9.000 | 11.000 | 13.500 | 2,10 | 3,29 | 4,74 | 184 | 318 | 452 |

| OT30 | 11.000 | 12.500 | 14.500 | 3,44 | 7,07 | 7,66 | 322 | 542 | 749 |

| OT36 | 8.500 | 11.500 | 12.000 | 3,35 | 6,85 | 7,35 | 322 | 542 | 749 |

| OT36S | 6.000 | 7.000 | 8.500 | 3,98 | 6,93 | 7,40 | 322 | 542 | 749 |

| Typ | A | B | C | D | E | F | X-Y |

|---|---|---|---|---|---|---|---|

| OT8 | 50 | 86 | 68 | 12 | 33 | 7 | 1/8″ |

| OT10 | 50 | 86 | 68 | 12 | 33 | 7 | 1/8″ |

| OT10S | 50 | 86 | 68 | 12 | 33 | 7 | 1/8″ |

| OT13 | 65 | 113 | 90 | 16 | 42 | 9 | 1/4″ |

| OT16 | 65 | 113 | 90 | 16 | 42 | 9 | 1/4″ |

| OT16S | 65 | 113 | 90 | 16 | 42 | 9 | 1/4″ |

| OT20 | 80 | 128 | 104 | 16 | 56 | 9 | 1/4″ |

| OT25 | 80 | 128 | 104 | 16 | 56 | 9 | 1/4″ |

| OT25S | 80 | 128 | 104 | 16 | 56 | 9 | 1/4″ |

| OT30 | 100 | 160 | 130 | 20 | 73 | 11 | 3/8″ |

| OT36 | 100 | 160 | 130 | 20 | 73 | 11 | 3/8″ |

| OT36S | 100 | 160 | 130 | 20 | 73 | 11 | 3/8″ |