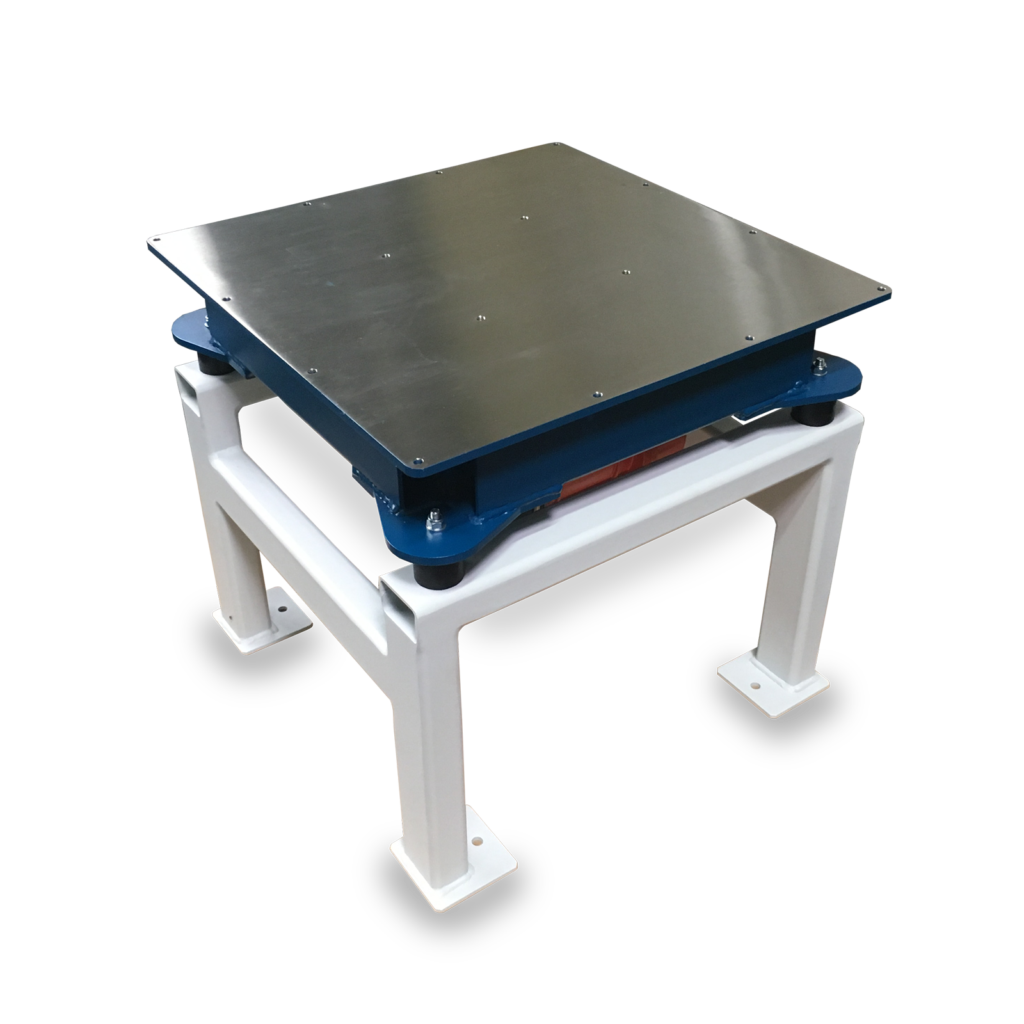

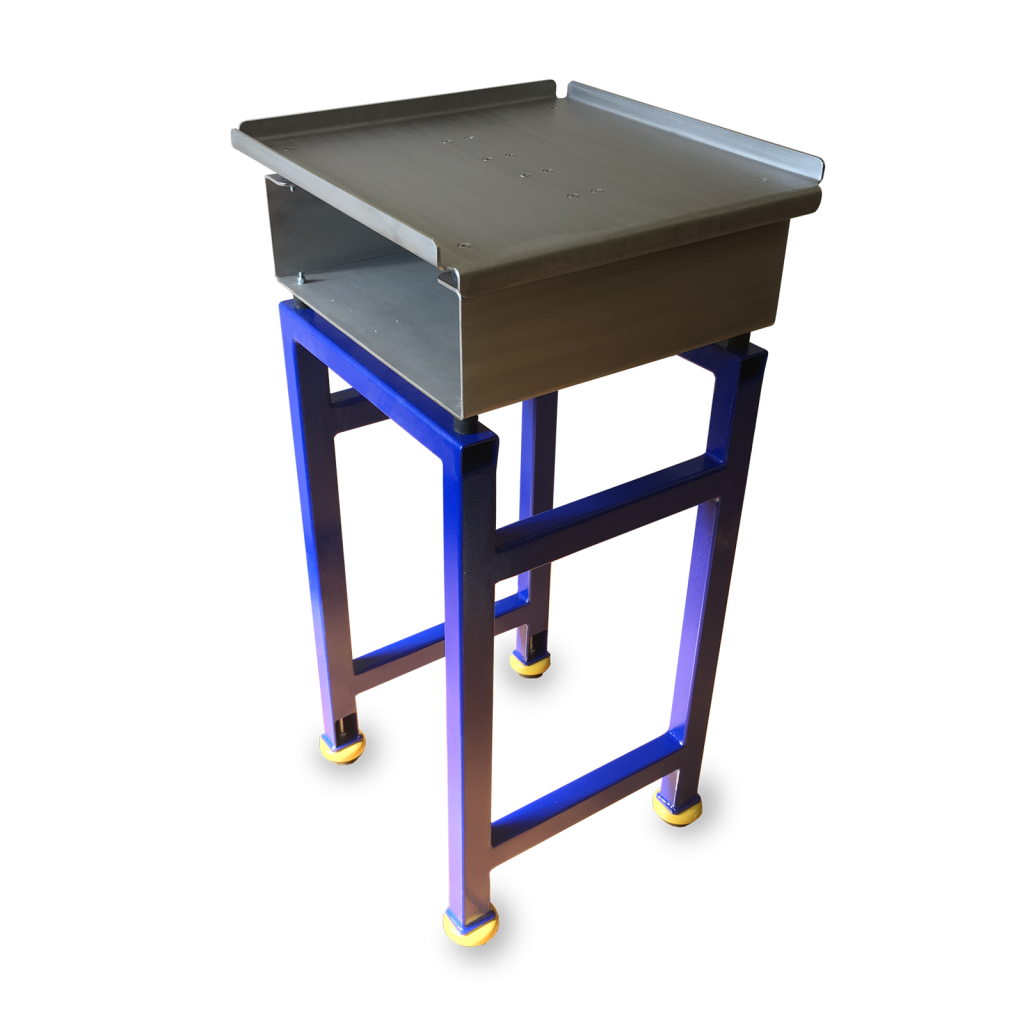

Vibrating tables for powder and bulk material

Our vibrating tables for powder and bulk material with linear vibration are suitable for general applications in compaction technology. Available in various standard sizes and mostly deliverable at short notice.

We will be happy to advise you to find a solution for your requirements. Please contact us!

- Bulk material

- Filling systems

- Possibilities

Our vibrating tables for powder and bulk material find their main application in the compaction of various bulk materials. Compaction of the bulk material may be necessary, for example, when sales or transport packaging must be filled. This allows the packaging to be optimally utilized in terms of volume.

Some of the tasks involved in compaction are:

- Compaction of loose bulk materials

- Filling in transport and sales packaging, BigBags, gabions, etc.

- Container emptying

- Venting of viscous media

Application using the example “Packaging of bulk material”

After the bulk material has been filled into its packaging, it is usually present in a loose bulk. There is air between the bulk material particles, which unnecessarily increases the volume in the packaging. Vibrations are generated with the aid of a vibrating table. These vibrations cause the bulk material particles to rearrange themselves, so that the lighter “air bubbles” rise and the bulk material particles move closer together. The result is that more powder/granulate/bulk material can be accommodated in the vibrated sales or transport packaging. The use of a vibrating table for powder and bulk material can be either as a stand-alone unit or as a fully integrated vibrating table assembly and part of the production or filling process.

In many filling processes, the use of a vibrating table or vibrating station is advantageous in order to fully utilize container sizes and obtain a uniform product. In this way, automated compaction, emptying or dewatering can be implemented in the process.

When filling the transport or sales packaging, it is easy for the product to be irregularly distributed and for the bulk density to be reduced. In order to even out the distribution and increase the filling quantity, it is useful to jog the packages at an oscillating table station. This can be done in intermittent operation with automatic raising and lowering, or even in continuous operation.

We build your perfect vibrating table!

Get an idea of the different designs of various vibrating tables developed and produced in our company.

Here you can get to our examples -> designs of vibrating tables